“Transforming your liquid

into perfect powder“

“Transforming your liquid

into perfect powder“

Why powder is often a better choice:

MEGGLE’s recipe for success has been for over 135 years: Tradition, quality and innovation. Founded in 1887 as a cheese dairy, MEGGLE Group has become a global brand with more than 2,500 employees, 20 locations worldwide and a turnover of 1.5 billion euros. Besides its well-known dairy products for consumers, MEGGLE manufactures high-quality pharmaceutical lactose, food- and feed ingredients and offers contract manufacturing services.

Business Unit Contract Manufacturing

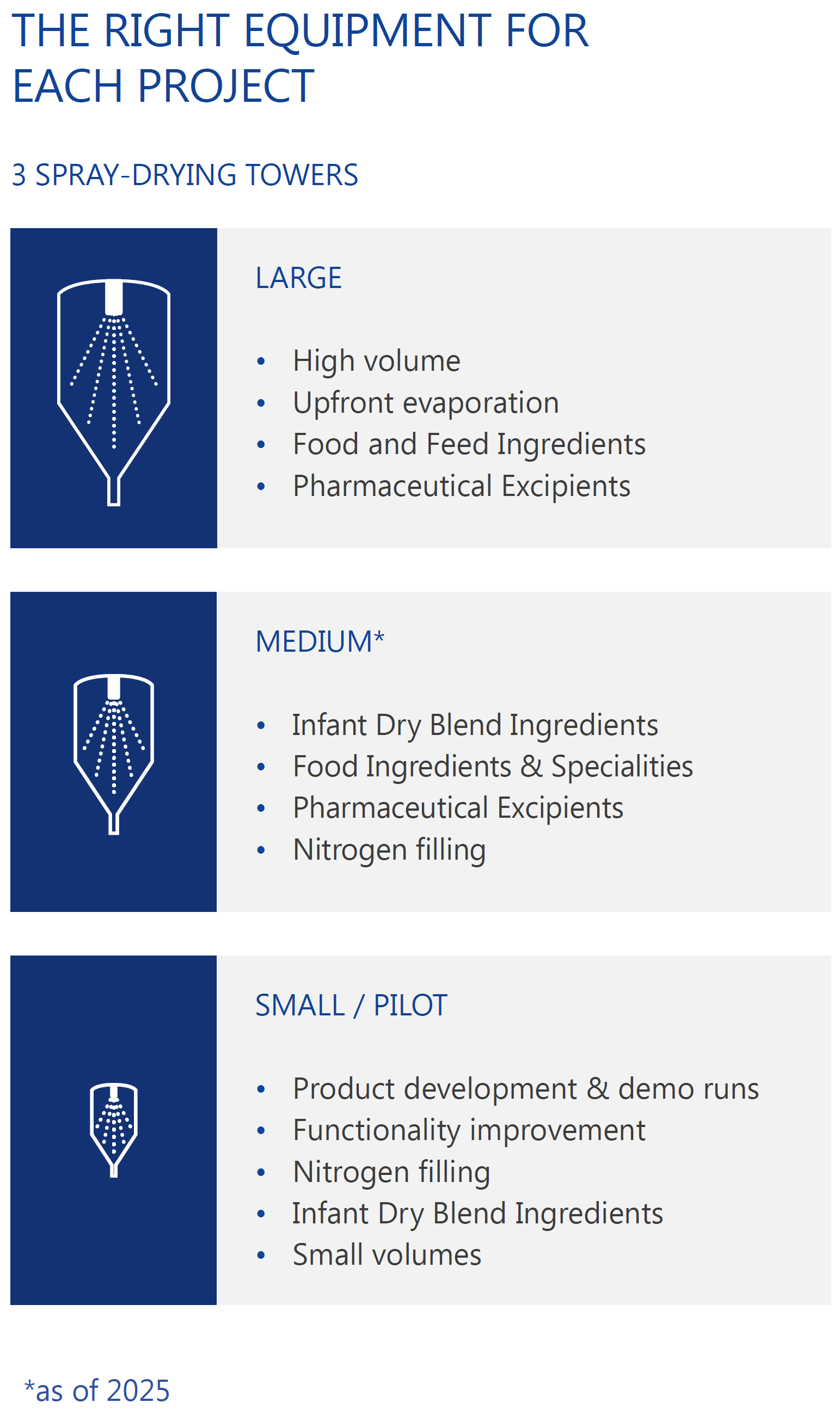

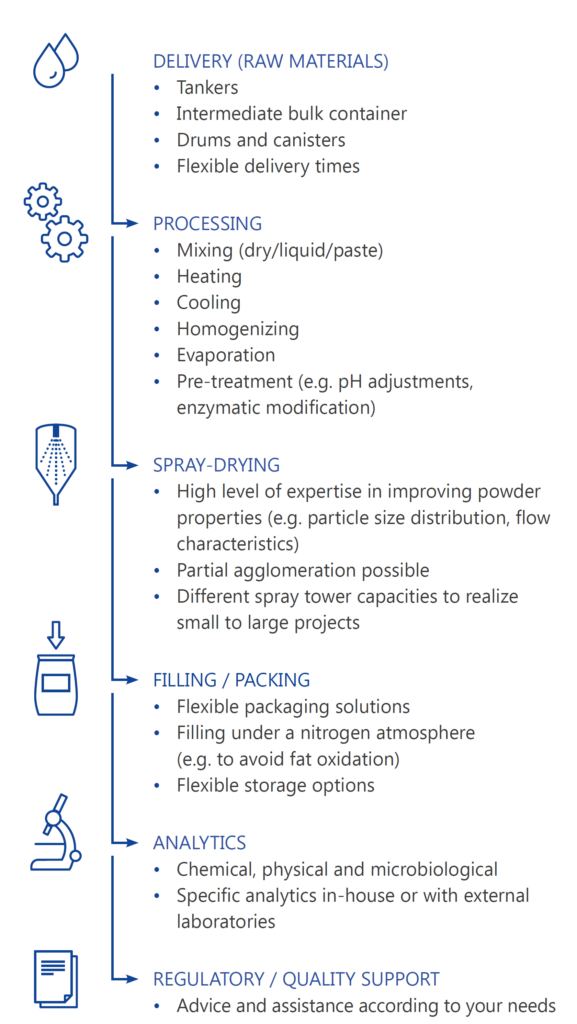

Our core competence in spray-drying is completed by agglomeration, evaporation and mixing services. We support our customers during development and production, offer tailor-made solutions and realize customer demands, no matter how unique they may be. Experience, long-term focus and intensive service from the very beginning ensure the success of your project.

We at MEGGLE have been producing spray-dried products since 1986 and have acquired a deep understanding of spray drying processes. That’s why we are your competent partner to realize your projects from the initial idea to the finished product.

Continuous wet agglomeration

with downstream fluid bed drying for the production of agglomerated products

Mixing of up to three powder substances possible

Falling film evaporator

from 10-55 MT of water evaporation per hour

Falling film evaporator

from 10-55 MT of water evaporation per hour

We have state-of-the-art production equipment and years of experience in developing and manufacturing ingredients. We are happy to share this know-how to make your project a success.

MEGGLE GmbH & Co. KG

Business Unit Contract Manufacturing

Megglestr. 6-12, 83512 Wasserburg am Inn

Germany

T +49 8071 73-336 or -699

info.contractmanufacturing@meggle.com

Let´s talk about your project!